PERC Cell

The PERC cell has a passivated rear side and a laser grooving process, which significantly improves the cell efficiency.

Bifacial PERC

For a bifacial PERC cell, the Al back surface field is replaced by Al grid, hence render the majority of rear side transparent which enable the cell to absorb light and generate electricity from both sides.

High Energy Yield

Outstanding low irradiance performance, low power-temperature coefficient, low operating temperature, all these technologies lead to a high energy yield.

Warranty

Based on the advanced mono wafer and anti-LID technology, We offers a first-year power warranty of ?98% for PV modules.

Cell Efficiency in

Mass Production

1st Year Degradation,

Anti-LID

Outstanding Low

Irradiance

Performance

Low Power

Temperature

Coefficient

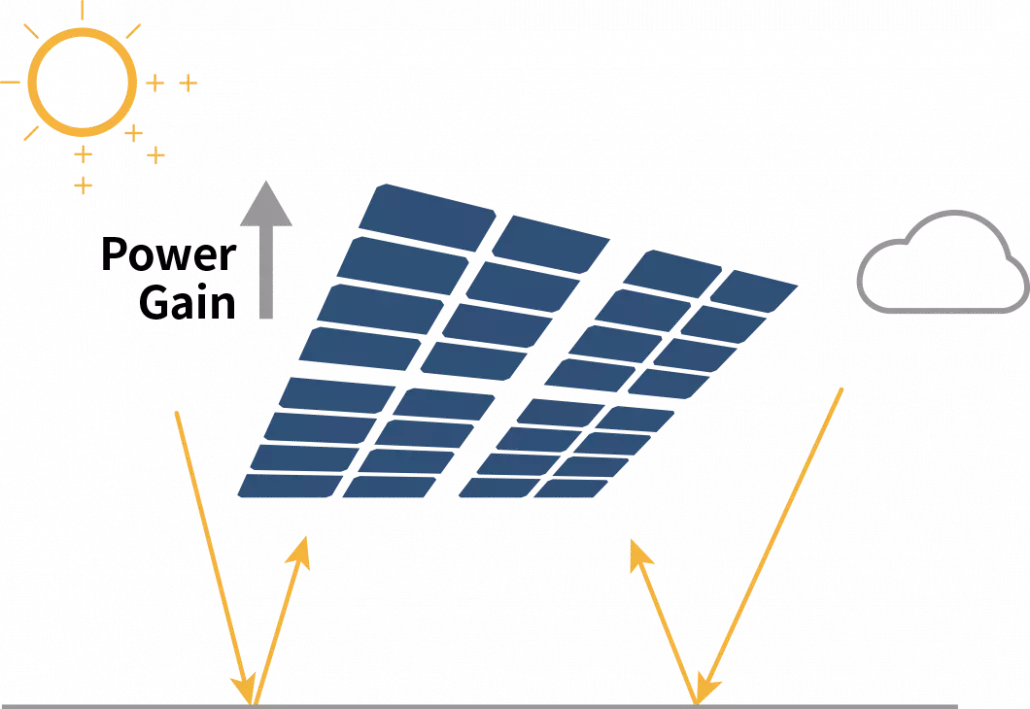

Bifacial Power Generation

The energy yield of bifacial module can be influenced by albedo, height of module, GCR and DHI etc. Installation height of bifacial module is recommended to be higher than 1m. Shading from bracket and junction box should be avoided. At present, the power generation of bifacial module on fixed brackets and single axis tracker can be simulated with PVsyst. Investors can determine the DC/AC ratio of bifacial module system to minimize the LCOE.

Albedo

It has considerable gains

on grass land, dry sand,

especially in snowfield

Module Height

High module height will

reduce the shading

impact on rear side. A

minimum of 1m is

recommended

GCR

A low GCR will increase

radiance on the rear side

DHI

Diffuse light can be

absorbed by the rear

side of the module. the

higher proportion of

Diffuse light, the higher

is the bifacial gain

Half-Cut Technology

Half-cut cell technology is to cut the cell into two seperate parts by mature infrared laser, hence halve the working current. The thermal loss on the ribbon will be remarkably reduced and the module’s power increases by 2%. The reliability of module is also enhanced.

The combination of half-cut cell technology and bifacial module can amplify the gain over the effect of current-reduction.

Hot Spot Temperature

In field applications, small area shadings can cause the temperature of those parts extremely high. This phenomena is called hot spot. The long duration of hot spot could bring irreversible degradation of modules.

Because the string current of half-cell modules is half of full-cell modules, the hot spot temperature can be obviously reduced. The experiments show that this reduction could be 10-20°C, which increases the module reliability.

Lower Operating Temperature

Half-cut cells have half of the working current, thereby the thermal loss is remarkably reduced. Operating temperature correspondingly decreases, and the reliability of module is improved as well as power gain.

Lower Shading Loss

Because of the unique parallel connection design, half-cell modules still have 50% power output under the circumstance of array shading in sunrise or sunset when portrait installation.

In addition, half-cut technology can improve the output of bifacial module under non-uniform incident illumination on the backside.

Higher Energy Yield Under High Irradiation Condition

Under high irradiation conditions, half-cell module, especially bifacial half-cell module, will have a higher energy yield compared with conventional module. Bifacial half-cell module will help to achieve the lowest LCOE in regions which is rich in sun radiation resources.